Product Lifecycle Management

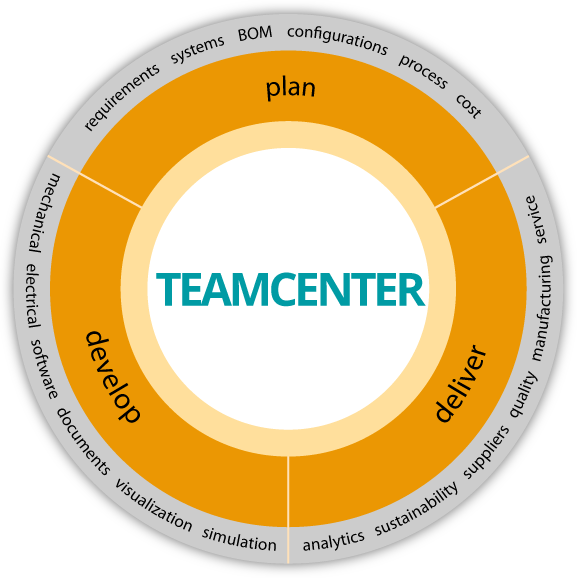

For companies that need to deliver increasingly complex products while maximizing productivity and streamlining global operations, Teamcenter is the leading choice for PLM.

Teamcenter provides a mechanism for you to take advantage of rich, best-in-class PLM capabilities, incorporate more voices into your PLM process, and do it all easier than ever before.

PRODUCT DATA MANAGEMENT

PLAN

Requirements Engineering

Model Based System Engineering

Bill-of-material Management

Product Configuration

Program, Project and Process Management

Product Cost Management

Open

Requirements Engineering:

Start compliant, stay compliant. Integrate requirements with the product lifecycle, enabling compliant by design products.

Model Based Systems Engineering:

Integrated systems engineering for everyone. Define and model systems, analyze options, optimize performance, and assess the impact of change to start integrated, stay integrated.

Bill-of-material management:

Know your product. A common source of BOM information provides a complete digital representation of the product, with coordinated evolution across domains.

Product Configuration:

More options, less effort.

Program, Project, and Process Management:

Get work done. Adaptable solutions ensure the right work and the right data are delivered to the right person at the right time.

Product Cost Management:

Control profitability. Cost transparency for products and tools enables you to make decisions based on quantifiable data for cost optimized products.

DEVELOP

Mechanical Design Management

Electrical Design Management

Software Design & Asset Management

Simulation Management

Document Management & Technical Publications

Lifecycle Visualization

Open

Mechanical Design Management:

Drive engineering productivity. Bring together MCAD data with the complete product definition.

Electrical Design Management:

Integrate ALM and PLM data and processes

Software Design & Asset Management:

Integrate ALM and PLM data and processes

Simulation Management:

Streamline simulation data and processes. Collaborate across the digital thread to manage simulation processes, data, tools and workflows to drive product development.

Document Management & Technical Publications:

One environment to manage documents and products together. Keep them synchronized, on schedule, accessible and compliant with standards.

Lifecycle Visualization:

Realize the potential of Digitalization. Visually share and collaborate on rich 3D multi-CAD product knowledge to catch errors earlier in the product lifecycle and communicate intent efficiently to downstream users.

DELIVER

Search & Analytics

Environmental Compliance & Product Sustainability

Supplier Integration

Quality Management

Manufacturing Planning

Service Lifecycle Management

Open

Search & Analytics:

Find more, search less. Enable all stakeholders to find what they need without wading through irrelevant information and interact with it in a meaningful way.

Environmental Compliance & Product Sustainability:

Ensure compliance. Integrate environmental data with product data at each phase of the product lifecycle

Supplier Integration:

Streamline supplier integration. Secure collaboration with your suppliers, asynchronously or in real-time, on a global scale.

Quality Management:

Closed Loop Quality Management for Design to Manufacturing. Connect the typically disconnected quality processes across the value chain.

Manufacturing Planning:

Manage the digital twin of production to help manufacturers predict and optimize performance in the real world.

Service Lifecycle Management:

Single source of service knowledge. Leverage design, manufacturing, and analysis data to provide accurate plans and information to support service activities.

ACTIVE INTEGRATION

Historically, digital systems for manufacturing enterprises have focused solely on one of three technological areas:

Business systems such as enterprise resource management (ERP) solutions offer information processing and management.

Product lifecycle management (PLM) solutions enable product creation and process engineering.

Manufacturing operations management (MOM) solutions such as manufacturing execution systems (MES) monitor and control production operations.

Get in touch to remove barriers between enterprise applications.

CRM System

ERP System

MES System

We are proud to be affiliated with

SIEMENS as our Digital Industries

Software partner.

ADDRESS

Old Paardevlei Road

Somerset West

Cape Town

7130

South Africa

GET IN TOUCH

Tel: +27 21 852 6450

Email: [email protected]